About I-VON

Pentex and i-VON have been working together for over 9 years to bring in-line measurement of your PET melt flow and to display its Intrinsic viscosity or I.V live, on the run to your operator whilst also being recorded every few seconds continuously.

With over 20 units in operation across the U.K alone, some for over 8 years now we have a long established history of supply and support to our existing customers in the implementation and operation of this truly invaluable tool. This ability to look into your process live and not have to wait the typical 6-8 hours for an offline MFI test allows live alteration of your regrind %, Bottle flake inclusion, and maybe perhaps your I.V chain extender if you use this. The ability to trace back your I.V also allows customer concerns to be better alleviated or responded to when you can prove the I.V at the time of production.

The i-VON brings its own R.o.I when just considering your ability to better stabilise your products end I.V through no longer having to add virgin as an insurance policy, to not only better tailor your I.V Chain extender (if you use one) but maybe to remove it entirely, to permit a higher regrind inclusion, to help to establish better – good – poor material suppliers and to once and for all answer internal quality questions around line I.V impact.

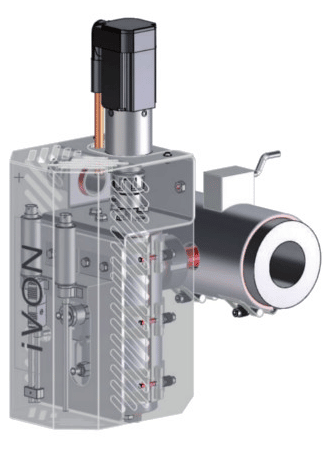

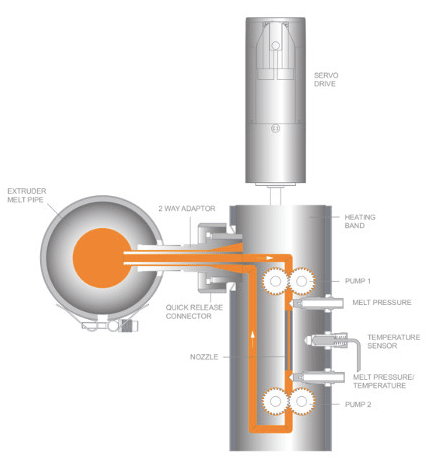

The i-VON helps to bring a total approach of full product traceability and compliance for all factors of the extrusion process and is simply installed in your melt flow, after your final filter and gear pump where it occupies very little space, consumes a measly amount of energy and sits with a zero waste in-line philosophy to silently stand witness over the I.V of your material.

Send us an enquiry to understand what the i-VON can bring to your process and how it can support your internal reduction of material cost whilst increasing your output I.V and so improve your finished products conversion efficiencies also.