colorlite

About colorlite

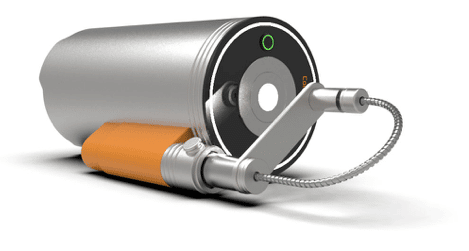

Colorlite brings to your production process and direct to your line the ability to monitor in real time the integrity of your colour and transparency all in one small footprint and operator-friendly format.

The ability to have an in-line photospectrometer making observations of your finished product continuously and arduously 24 hours a day makes for total traceability but even more than this – total value from your additive costs.

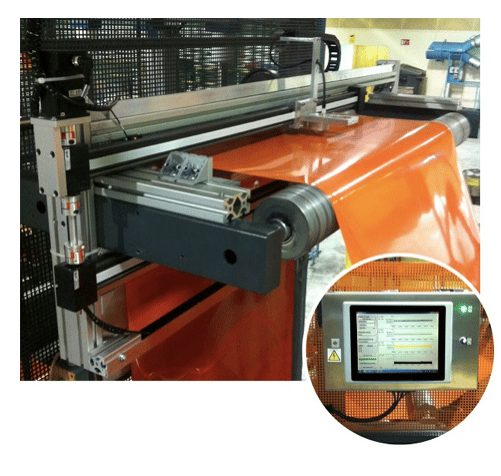

Operators can now make alterations in-process without having to leave the line side and see real-world feedback instantaneously. This powerful addition to your operators’ Quality systems gives total flexibility to make compensatory changes to your colourant addition rates to ensure not just full compliance to your end customer but also to your bottom line for material costs. In another way, you may want to achieve the most addition of a-PET/PE into your clear mix whilst complying with your set haze value – this can be done, want to reduce your operational costs of optical brightener in your recipe – this can be done, want to achieve the lowest cost raw material blend whilst maintaining a ‘just enough’ addition rate – this can be done.

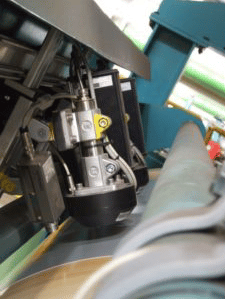

The pairing of the Colorlite system to the REPI doser can also fully automate this process, something that actually means you normally use far less of the additive than when running with a manual set point. Just how many times how you been line side or heard feedback from the shop floor, ‘Yes 2% was covering the requirement but it been set to 3% just to be safe…’ this is no longer required when automating the process with your colorlite and REPI combined system.

Colorlite and Pentex can bring total clarity to your process colourant and haze measurement, totally in regard to traceability also. Talk with us to understand the best equipment for your process.