WM Thermoformer

About WM

WM thermoforming technologies are presented in the U.K & Ireland by Pentex and its with great pride and honour that this Family business with over 40 years of manufacturing knowhow and thermoforming expertise has, its expansion and growth is earned from superior customer support and technological respect of the materials its machines process.

WM originally founded in 1981 has grown from a concept business to one that covers the globe in flat and tilt bed thermforming machines. Our machines can be found in technical, food & pharma applications and are used by companies of all sizes who know that WM will be with you not just for the purchase but for the first year, fifth year and always by your side. WM’s respect for the materials its customers process means our technologies have the correct advantages to aid and facilitate leading advantages in performance, quality, efficiency and technology.

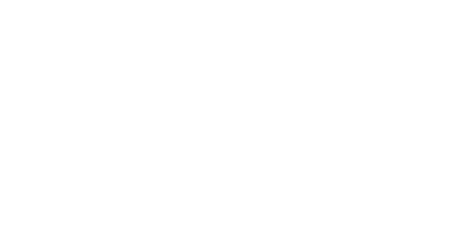

FLEX 92: Vacuum and pressure thermoforming machine with steel rule cutting, the only machine able to fit most of your steel rule die cutting moulds.

FC Series: Vacuum and pressure thermoforming machines with steel rule die cutting, for customers who must fulfill both the medium-high productivity and the flexible productions.

FT and TWIST Series: In-mould trimming thermoforming machines with lower tilting platen, suitable for high quality products with me- dium-long term production, and to be completed with a wide range of automatic stacking devices according to the final product.

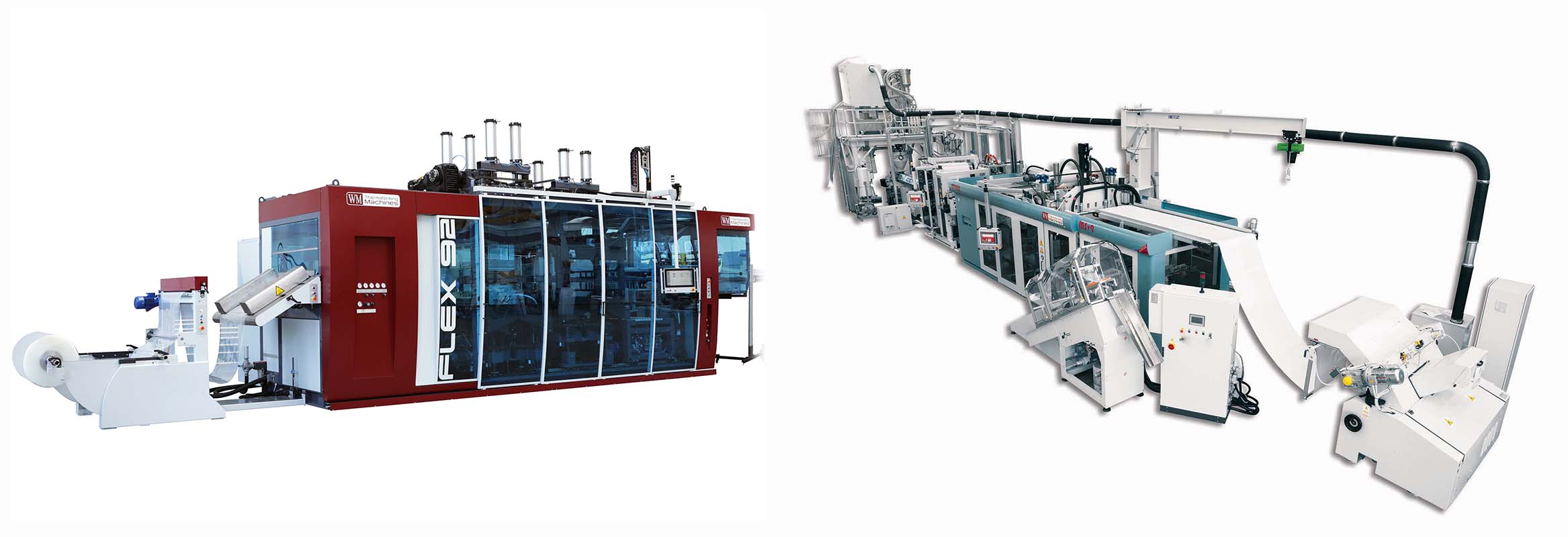

COMPLETE IN-LINE PLANTS: Real production islands including she- et extrusion, thermoforming, direct recycling of the scrap, up to the final product packaging. The most efficient system to produce disposable cups, plates, margarine tubs and yogurt containers.

Extruder N.EXT: Includes screw diameters of 30-45-75 mm, L/D ratio of 36 and output capacity from 450 to 900 Kg/h for Polypropylene material with a high percentage of regrind. Reduced installed power and cooling.

Rim Rolling machine: Rim rolling machinery for customers who are looking for improved product quality of disposable cups made of Poly- styrene, Polypropylene, APET or PLA.

Pre-heating units: All thermoforming machines can be completed by a pre-heating oven with easy sheet feeding, optimal insulation and high efficiency in the heating distribution.

Having experience and total machine implementation and ownership from just a simple form & cut station to machines having pre-heater, form, hole punch, cut and robot stacker but also with total in-line solutions from raw material (virgin / recycled / in-house) to sheet, formed product, cut and stacked, roll rimmed if required, collated, sleeved, etc. The many installations of WM demonstrate the knowledge we have, the customer confidence in WM and the continued growth our customers continue to benefit from.

WM have forged themselves as a different level of supplier and equipment partner with on hand aftersales service and support, this is offered both through the WM team based in Stabio, Switzerland and continued here in the U.K & Ireland by our U.K based team. The longevity of our machines is matched always by the commitment for support and continuous improvement given remotely and in person. Working with WM and Pentex gives you the knowledge of a presence always available in the background to assist in your continued progress and development as a user and as a supplier to your customer.

We know that companies take serious decisions within serious timelines. We are here to present WM and to ensure that we are present and ever ready to discuss your thermoforming needs from simple and small form-cut-stack configurations right up to extrusion-form-roll rimming-sleeving and collating applications. Talk with us to understand how Pentex and WM can work with you to grow or even start your businesses thermoforming journey.